Uncategorized

Understanding the Role of Digital Twins in the Construction Industry

As technology continues to evolve, the construction industry is rapidly transforming. One of the latest technological advancements that have gained popularity in recent years is the concept of digital twins. Digital twins are a virtual representation of a physical object or system, and they are becoming increasingly prevalent in the construction industry. In this article, we will explore the role of digital twins in the construction industry and how they are transforming the way we design, construct, and manage buildings.

Introduction

Digital twins are virtual models that replicate physical objects or systems. They are created by integrating data from various sources, such as sensors, drones, and other Internet of Things (IoT) devices. Digital twins can provide a comprehensive view of a physical object or system, enabling us to simulate its behavior and performance in different scenarios. In the construction industry, digital twins are becoming an essential tool for architects, engineers, and builders, allowing them to optimize the design, construction, and maintenance of buildings.

The Benefits of Digital Twins in Construction

Digital twins offer several benefits in the construction industry, including:

- Better Design

Digital twins allow architects and engineers to create a more accurate and efficient design for buildings. By simulating the behavior of the building in a virtual environment, they can identify potential design flaws and make necessary changes before construction begins. This saves time, reduces costs, and ensures that the building is optimized for its intended use.

- Improved Construction

Digital twins can also improve the construction process by providing real-time information about the project’s progress. By using sensors and other IoT devices, builders can monitor the building’s construction in real-time, identify any potential issues, and make necessary changes quickly. This helps to reduce delays, improve efficiency, and ensure that the project is completed on time and within budget.

- Enhanced Maintenance and Management

Digital twins can also be used to manage and maintain buildings more effectively. By monitoring the building’s performance in real-time, building owners can identify any potential issues before they become major problems. This helps to reduce maintenance costs, improve the building’s performance, and extend its lifespan.

Use Cases of Digital Twins in Construction

Digital twins are already being used in various applications in the construction industry, such as:

- Building Design and Planning

Architects and engineers use digital twins to create accurate models of buildings, test their performance in different scenarios, and optimize their design for maximum efficiency.

- Construction Management

Builders use digital twins to monitor the progress of construction in real-time, identify any potential issues, and make necessary changes quickly.

- Building Maintenance

Building owners use digital twins to monitor the building’s performance in real-time, identify any potential issues, and schedule maintenance activities accordingly.

Challenges of Implementing Digital Twins in Construction

While digital twins offer several benefits in the construction industry, there are also some challenges that need to be addressed, including:

- Cost

Creating digital twins can be costly, especially for complex projects. The cost of sensors, IoT devices, and other equipment needed to create digital twins can be prohibitive for some construction projects.

- Data Integration

Digital twins require data from various sources, such as sensors, drones, and other IoT devices. Integrating this data can be challenging, especially when dealing with large amounts of data.

- Skills Gap

Creating and managing digital twins requires specialized skills and expertise, which may not be readily available in the construction industry.

Conclusion

Digital twins are transforming the construction industry by offering a more efficient and effective way to design, construct, and manage buildings. They offer several benefits, including better design, improved construction, and enhanced maintenance and management. However, there are also some challengesto implementing digital twins in construction, such as cost, data integration, and skills gap. As technology continues to evolve, we can expect these challenges to be addressed, and digital twins to become an increasingly integral part of the construction industry.

FAQs

- What is a digital twin in the construction industry?

A digital twin is a virtual representation of a physical object or system that can be used to simulate its behavior and performance in different scenarios. In the construction industry, digital twins are becoming an essential tool for architects, engineers, and builders, allowing them to optimize the design, construction, and maintenance of buildings.

- How are digital twins used in building design and planning?

Architects and engineers use digital twins to create accurate models of buildings, test their performance in different scenarios, and optimize their design for maximum efficiency.

- What are the benefits of using digital twins in construction?

Digital twins offer several benefits in the construction industry, including better design, improved construction, and enhanced maintenance and management.

- What are the challenges of implementing digital twins in construction?

The challenges of implementing digital twins in construction include cost, data integration, and skills gap. Creating and managing digital twins requires specialized skills and expertise, which may not be readily available in the construction industry.

- What is the future of digital twins in the construction industry?

As technology continues to evolve, we can expect digital twins to become an increasingly integral part of the construction industry. With advancements in IoT devices, data analytics, and machine learning, digital twins will become even more powerful tools for designing, constructing, and managing buildings.

Uncategorized

21 Banned Gadgets You Can Still Buy on Amazon

21 Banned Gadgets You Can Still Buy on Amazon

With the rise of technology, gadgets have become an integral part of our lives.

From smartphones to smartwatches, we have access to a variety of gadgets that make our lives easier. However, not all gadgets are legal to use in certain countries, and some have even been banned due to safety concerns.

Despite this, there are still many banned gadgets that you can buy on Amazon.

In this article, we will discuss 21 banned gadgets that are still available for purchase on Amazon.

1. Laser Pointers

Laser pointers may seem harmless, but they have been banned in many countries due to their potential to cause eye damage. However, you can still find a variety of laser pointers on Amazon, ranging from low-powered to high-powered.

2. Nunchucks

Nunchucks are a popular weapon in martial arts, but they have been banned in many countries due to their potential to cause harm. However, you can still purchase nunchucks on Amazon, although they may not be legal to use in certain countries.

3. Electronic Cigarettes

Electronic cigarettes have been banned in several countries due to their potential health risks. However, you can still buy electronic cigarettes on Amazon, although they may not be legal to use in certain countries.

4. Spy Cameras

Spy cameras have been banned in several countries due to privacy concerns. However, you can still buy spy cameras on Amazon, although you should be aware of the legal restrictions regarding their use.

5. Tasers

Tasers have been banned in several countries due to their potential to cause harm. However, you can still purchase tasers on Amazon, although they may not be legal to use in certain countries.

6. Lock Picks

Lock picks have been banned in several countries due to their potential to aid in illegal activities. However, you can still purchase lock picks on Amazon, although you should be aware of the legal restrictions regarding their use.

7. Bump Keys

Bump keys are used to pick locks and have been banned in several countries due to their potential to aid in illegal activities. However, you can still buy bump keys on Amazon, although you should be aware of the legal restrictions regarding their use.

8. Knives

Certain types of knives, such as switchblades and butterfly knives, have been banned in several countries due to their potential to cause harm. However, you can still find a variety of knives on Amazon, although you should be aware of the legal restrictions regarding their use.

9. Stun Guns

Stun guns have been banned in several countries due to their potential to cause harm. However, you can still purchase stun guns on Amazon, although they may not be legal to use in certain countries.

10. Gas Masks

Gas masks have been banned in several countries due to their potential to be used for illegal activities. However, you can still buy gas masks on Amazon, although you should be aware of the legal restrictions regarding their use.

11. Brass Knuckles

Brass knuckles have been banned in several countries due to their potential to cause harm. However, you can still buy brass knuckles on Amazon, although they may not be legal to use in certain countries.

12. Pepper Spray

Pepper spray has been banned in several countries due to its potential to cause harm. However, you can still purchase pepper spray on Amazon, although it may not be legal to use in certain countries.

13. Shortwave Radios

Shortwave radios have been banned in several countries due to their potential to be used for illegal activities. However, you can still buy shortwave radios on Amazon.

14. Batons

Batons have been banned in several countries due to their potential to cause harm. However, you can still purchase batons on Amazon, although they may not be legal to use in certain countries.

15. Knuckle Dusters

Knuckle dusters have been banned in several countries due to their potential to cause harm. However, you can still buy knuckle dusters on Amazon, although they may not be legal to use in certain countries.

16. Wireless Jammers

Wireless jammers have been banned in several countries due to their potential to interfere with wireless signals. However, you can still purchase wireless jammers on Amazon, although you should be aware of the legal restrictions regarding their use.

17. Body Armor

Body armor has been banned in several countries due to their potential to be used for illegal activities. However, you can still buy body armor on Amazon, although you should be aware of the legal restrictions regarding their use.

18. E-Books

Certain e-books have been banned in several countries due to their content. However, you can still purchase banned e-books on Amazon, although you should be aware of the legal restrictions regarding their use.

19. Bongs

Bongs have been banned in several countries due to their potential to be used for illegal activities. However, you can still buy bongs on Amazon, although you should be aware of the legal restrictions regarding their use.

20. Brass Knuckle Belt Buckles

Brass knuckle belt buckles have been banned in several countries due to their potential to cause harm. However, you can still purchase brass knuckle belt buckles on Amazon, although they may not be legal to use in certain countries.

21. Self-Defense Keychains

Self-defense keychains have been banned in several countries due to their potential to cause harm. However, you can still buy self-defense keychains on Amazon, although they may not be legal to use in certain countries.

As you can see, there are a variety of banned gadgets that you can still buy on Amazon. However, it is important to be aware of the legal restrictions regarding their use, as using these gadgets in certain countries may result in legal consequences.

In conclusion, while there are several banned gadgets that you can still buy on Amazon, it is important to be aware of the legal restrictions and potential risks associated with using them.

By conducting thorough research before making a purchase, you can ensure that you are using these gadgets responsibly and legally, and minimize the potential risks associated with using them.

The Importance of Conducting Research Before Purchasing Banned Gadgets

While it may be tempting to purchase banned gadgets on Amazon, it is important to conduct thorough research before making a purchase. This research should include:

- Legal Restrictions: It is important to check the legal restrictions regarding the use of these gadgets in your country before purchasing them. Using these gadgets in a manner that violates legal restrictions may result in legal consequences.

- Potential Risks: Many of these gadgets have the potential to cause harm or be used for illegal activities. It is important to understand the potential risks associated with using these gadgets and to use them responsibly and legally.

- Seller Reputation: It is important to research the reputation of the seller before making a purchase. This can include reading reviews, checking for return policies, and verifying the seller’s credentials.

- Product Quality: While these gadgets may be banned, it is still important to ensure that they are of good quality and will function as intended. Researching the product and reading reviews can help you make an informed decision.

By conducting thorough research before making a purchase, you can ensure that you are using these gadgets responsibly and legally, and minimize the potential risks associated with using them.

FAQs

- Are there any legal consequences for purchasing these banned gadgets?

The legal consequences may vary depending on the country you are in and the legal restrictions regarding the use of these gadgets. It is important to research the legal restrictions before making a purchase. - Can these banned gadgets be returned?

It depends on the seller’s return policy. It is important to check the return policy before making a purchase. - Can these banned gadgets be used for self-defense?

Many of these gadgets have the potential to be used for self-defense, but it is important to research the legal restrictions regarding their use and to use them responsibly. - Can I trust the sellers on Amazon to sell good quality banned gadgets?

It is important to research the reputation of the seller before making a purchase. This can include reading reviews, checking for return policies, and verifying the seller’s credentials. - Should I report the sale of banned gadgets on Amazon?

If you believe that a seller is selling illegal or banned gadgets on Amazon, you should report it to Amazon and/or the relevant authorities. - Are all the gadgets listed on Amazon legal to use in my country?

It is important to check the legal restrictions regarding the use of these gadgets in your country before purchasing them. - Can I bring these gadgets with me when traveling internationally?

It is important to research the laws of the country you are traveling to before bringing these gadgets with you. - Are there any potential risks associated with using these gadgets?

Yes, many of these gadgets have the potential to cause harm or be used for illegal activities. It is important to use them responsibly and legally. - Can Amazon be held liable for selling these banned gadgets?

Amazon is not responsible for the legal use or misuse of the gadgets that they sell. - Are there any penalties for using these banned gadgets?

Yes, using these gadgets in a manner that violates legal restrictions may result in legal consequences.

You cannot refer to any packaging determination as excellent packaging, as everyone has their own potential. However, we are not well-disposed with this statement as per we suggest you outstanding packaging for your things. In this esteem, you can witness Cartridge Boxes by way of they have completed these structures that create them occasionally and matchless. Though the colors used in this packaging are striking, and people also choose them because they trust their performance. So, the only item that matters is secure delivery with completely safe choices for your things. Thus, these boxes are excellent in all the traditions that describe your goods properly.

Shape and Design of your Wonderful Cartridge Boxes

Time has transformed as some online companies suggest you plan your own explanation. Hence, you can choose your own grace and design for your creations’ packaging with imaginative items. Additionally, you can create this design choice in making your Cartridge Boxes as they have special styling. Therefore, these boxes will aid you in forming your things in the means you want them to twin. In this respect, your branded stuff desires somewhat that brings them good coverage; thus, these boxes are the best prime. In addition to this, you can find them durable as they exert for your products’ improvement. These boxes have extremely outstanding and excessive designs and shapes.

Design Your Cartridge Boxes with 3D Things

Henceforth, 3D visuals are the up-to-date item that makes your packaging striking and good-looking. In accumulation to this, these designs add a rare touch to your goods with the aim of their exclusivity. So, Cartridge Boxes with entirely 3D designs make your things number one and unique. So, these boxes will aid you in featuring your things with all the up-to-date methods. In this esteem, it will also provide benefits for the firm as individuals discover your things are made from up-to-date methods. Thus, this factor will make them common in the market, and people will want to purchase them. In this way, this packaging aids in improving sales also.

Cartridge Boxes Bring Innovative Designs to Your Life

Moreover, we all have creative minds, but then all of us don’t demand a correct stage to show them off. Therefore, you are sanctified to display your volume with the aid of the Cartridge Boxes we propose you style them. In accumulation to this, you can take your creative ideas, and we an effort for you by ways of it is similar to the needs come exact for you. Additionally, we work hard; therefore, that we carry work that is external to your expectations. In this respect, these boxes will profit you a lot in creating your goods productive in the whole market. As a consequence, we can say that these boxes bring innovative ideas to the life of clients and are also very attractive to them.

CBD Boxes are ideal for Numerous Products

Perfect packaging boxes are perfect for your business or your consumers. The packaging is complete with a strong wood body and ultimate style; the CBD Boxes are sure to aid their purpose well. Furthermore, they feature outstanding designs and shapes that easily spread buyers’ consideration and creating it easy to determine what they’re watching for. In this respect, this packaging is simple to practice; the first-class inner styles them perfect for numerous cosmetics things like talcum powder and other minor stuff. Also, these boxes are harmless packaging significant for your cosmetics, accessories, beauty goods, and other goods as well.

Amazing Aspects of Outstanding CBD Boxes

As a leading creator and dealer of packaging boxes. Furthermore, these boxes manufacture with superior raw things obtained from genuine sellers. Hence, they offer a striking finish with gem-clear lids perfectly designed to grasp your essential things. The practice of CBD Boxes is to retain the things you demand to trade in a store. Likewise, these boxes are imperative by means they can retain various goods safely and well. They ascend in varied shapes, dimensions, colors, and many designs. You can choose the finest boxes giving to your needs and budget.

Get a Safe Solution in the Procedure of CBD Boxes

For many, they are a disturbance to conveyance while traveling. It is exhilarating to accomplish the goods, and you want to be apprehension about how you will take your CBD Boxes at a similar time. Additionally, there may be plenty of selections available in the market, but extreme of them do not result from bout to be reliable and harmless for you. Moreover, style your various things available for consumers safely and suitably with these striking boxes. In accumulation to this, it is ideal for storing various things and goods.

Uncategorized

10 Habits Of Highly Successful And Happy People

Are you looking for ways to be successful and happy? If so, then you have come to the right place. In this blog post, we will be exploring ten habits of highly successful and happy people that you can start implementing in your life. From living with the purpose to prioritizing mental and physical health, these habits will help you become the successful and happy individual that you have been dreaming of. Let us get started!

Read More Article: Evan Gilbert-Katz Documentary Filmmaker

1. They Live With Purpose

Starting each day with purpose and intention is a key part of living a meaningful life. By starting your day with a clear goal in mind, you can start to focus on the tasks at hand and make progress toward your objectives. When you’re working towards something that’s important to you, it becomes easier to stay motivated.

Spending time doing activities that you love is also essential for living a meaningful life. Doing things that make you happy helps to reduce stress and increase happiness – two key ingredients for achieving success. Pursue goals that are challenging but worth achieving, and don’t forget about the importance of relationships in your journey. Be sure to spend time interacting with people who make you feel good – relationships are one of the most important keys to happiness. Finally, practice self-reflection and mindfulness so that you can stay aware of your surroundings and manage stress more effectively.

When it comes to celebrating milestones or achievements in life, take care not to overdo it. Celebrate in a way that feels genuine and true to yourself, rather than trying to conform to society’s expectations. Live life on your terms and don’t let anyone tell you what’s right or wrong – this is the key to living an authentic life.

How To Find Meaning And Fulfillment In Life

Finding meaning and fulfillment in life can be a challenge. It can be easy to get wrapped up in our day-to-day lives and forget to take the time for ourselves. This is why it’s so important to prioritize self care and mental health. Taking the time for yourself will allow you to stay balanced, motivated, and productive.

When it comes to setting goals, it’s important to be realistic but also aspirational. Set goals that are challenging but achievable, and make sure that you meet them as often as possible. This will help you feel accomplished and fulfilled – two key ingredients for happiness.

It’s also important to make connections with others. Connect with people who share your interests, who can provide advice or support when needed, and who you can learn from. Building relationships is one of the most rewarding things that you can do in life – don’t miss out by focusing on your relationships at the expense of other aspects of your life.

Practice gratitude every day – especially when times are tough. It can help you feel positive about your current situation, which will help you stay positive during difficult times. Positivity is key when striving for happiness – remember to focus on the good things in life instead of dwelling on the negative aspects all the time.

2. They Prioritize Mental And Physical Health

Mental and physical health are two intertwined concepts that should be taken into account when trying to maintain a healthy lifestyle. When you are mentally and physically healthy, you are able to handle stress and difficulty more easily. Below, we will outline the key points that impact mental and physical health and how sleep, stress, nutrition and exercise play a role.

When it comes to mental health, getting enough sleep is essential. Most people need at least 7 to 8 hours of good quality sleep each night in order to function at their best. If you’re not getting enough sleep, your mood will suffer as well as your ability to think straight. In addition to getting enough sleep, make sure that you’re eating nutritious meals that include a variety of fruits and vegetables. This will provide your body with the vitamins, minerals, and other nutrients it needs for optimal health.

Stress is another important factor when it comes to mental health. Too much stress can have negative effects on both your physical and mental health. Therefore, it’s important to find ways to reduce or manage stress throughout the day. One way is by scheduling in time for light exercise every day – even if it’s just 10 minutes of walking outdoors! Spending time outdoors whenever possible also helps reduce stress levels – whether you’re taking a walk in nature or enjoying a sunny day at the beach.

Must Read Article: The Effects Of Climate Change-A Global Crisis And Its Solutions

3. They Set Goals And Take Action

Everyone has goals, but not everyone knows how to achieve them. Too often, people set goals without any plan or strategy to get there. This can be frustrating and lead to failure. Instead of trying to do everything at once, focus on taking one step at a time and working towards specific goals.

By planning your days and prioritizing tasks, you’ll be able to better manage your time and reach your objectives. Set realistic goals that you can attain in the short term and long term, and take action towards them every day. Have an open mind about things and don’t be afraid to experiment – sometimes the best ideas come from outside of our comfort zone.

Build positive relationships with others – it’s easy to get lost in the rat race when we’re trying to achieve our goals, but it’s essential for success. Carefully select friends and family members who will help support you as you journey towards your dreams. Live a healthy lifestyle both mentally and physically by eating balanced meals, getting enough sleep, exercising regularly, etc. Finally, take time for yourself every day – whether that means going for a walk or relaxing with a good book in your favorite chair. By taking these simple steps, you’re on your way to achieving success!

To Wrap Things Up

Living a successful and happy life requires dedication and hard work, but with the right habits in place, anything is possible. Habits such as living with purpose, taking care of your mental and physical health, setting goals, and taking action will help you reach your goals while still feeling fulfilled. Lastly, remember to be mindful of your actions – practice self-reflection often so that you can stay true to yourself. Take these habits into consideration as you journey towards success – it will make all the difference!

-

Education2 years ago

Education2 years agoCreating Engaging And Relevant Content As A Literacy Influencer

-

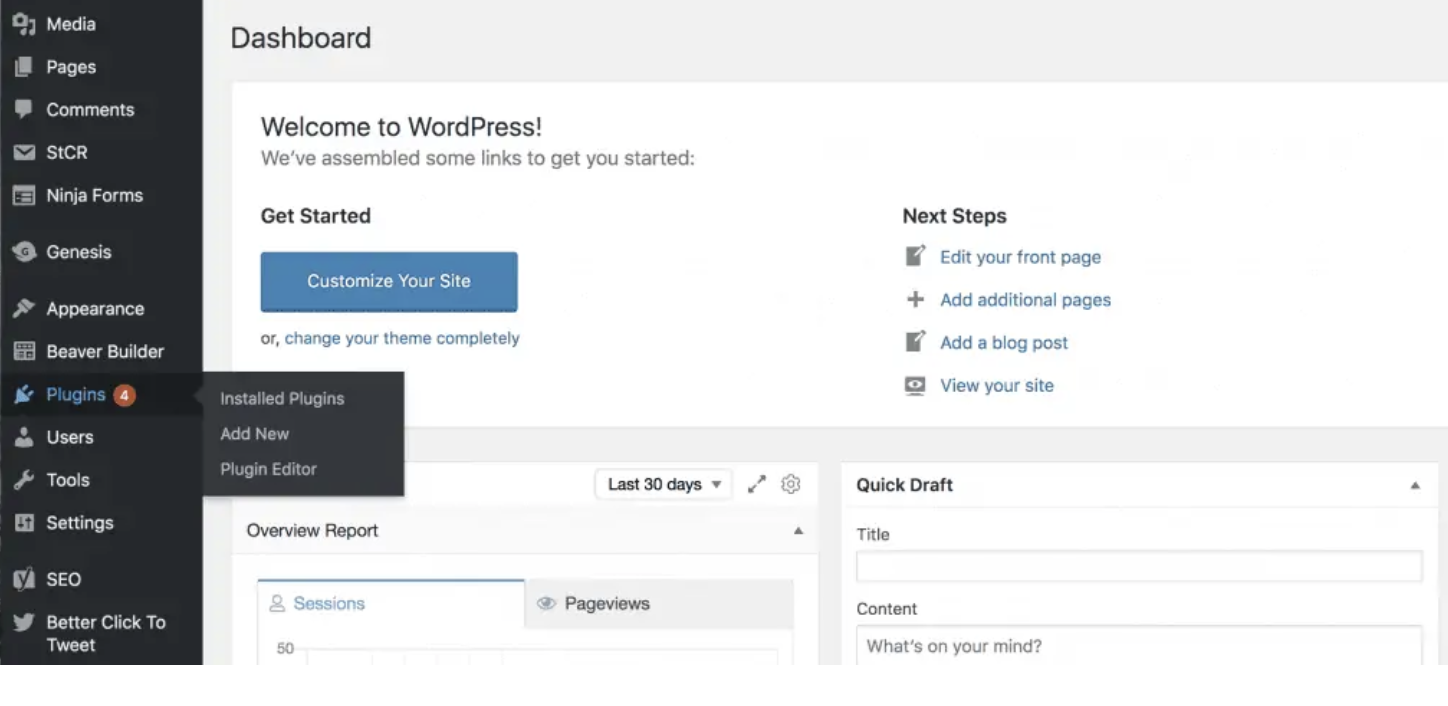

Internet3 years ago

Internet3 years agoWhat Are the Differences Between WP Rocket, RocketCDN and Cloudflare

-

How To..3 years ago

How To..3 years agoWhat Is Better Than Safety Deposit Box

-

Mobile Phones3 years ago

Mobile Phones3 years agoKnow About the New Upcoming Mobile Phones

-

SEO2 years ago

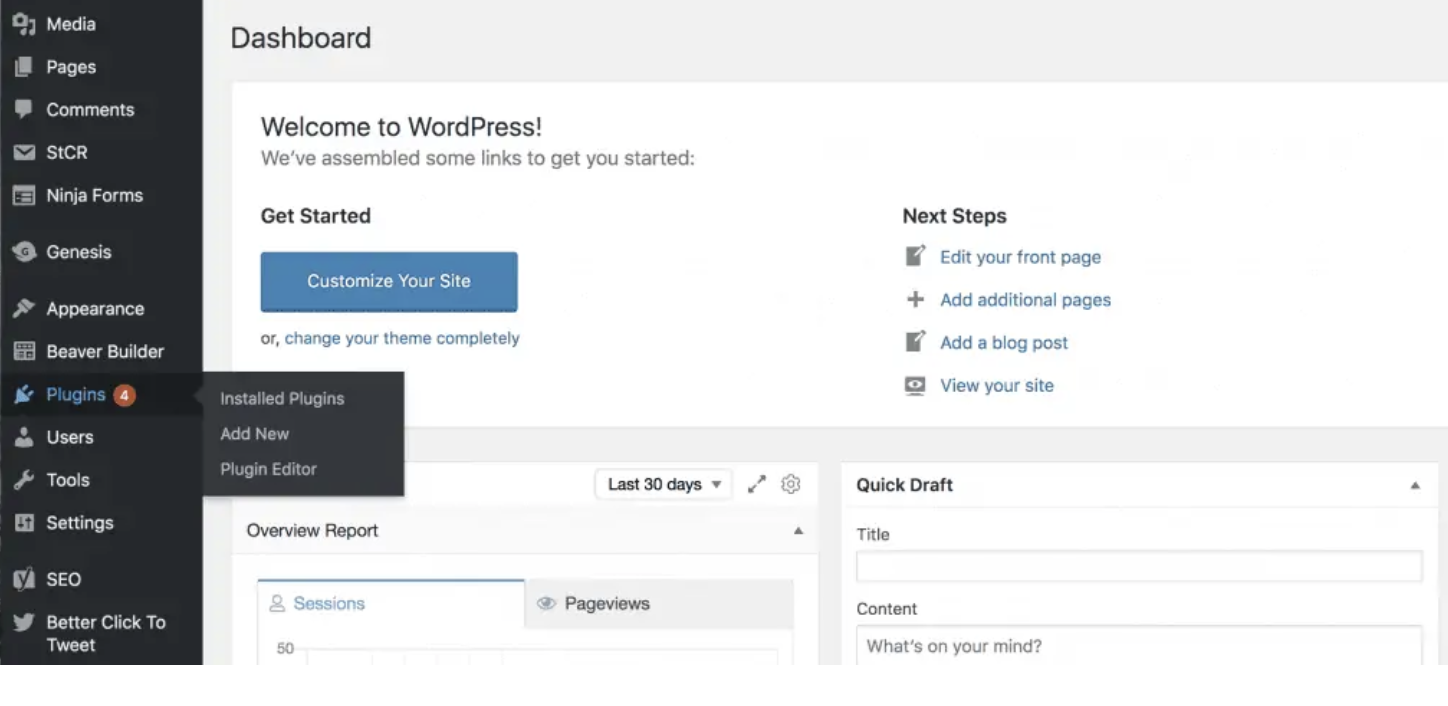

SEO2 years agoWordPress: How to Fix ‘Add New Plugin Menu Not Showing

-

Software2 years ago

Software2 years agoWhy is Content Workflow Software Necessary for Content Production

-

Digital Marketing1 year ago

Digital Marketing1 year ago13 Possible Reasons Why Your Google Ads Are Not Showing Up

-

TVs2 years ago

All You Need to Know About the Toman Tokyo Revengers